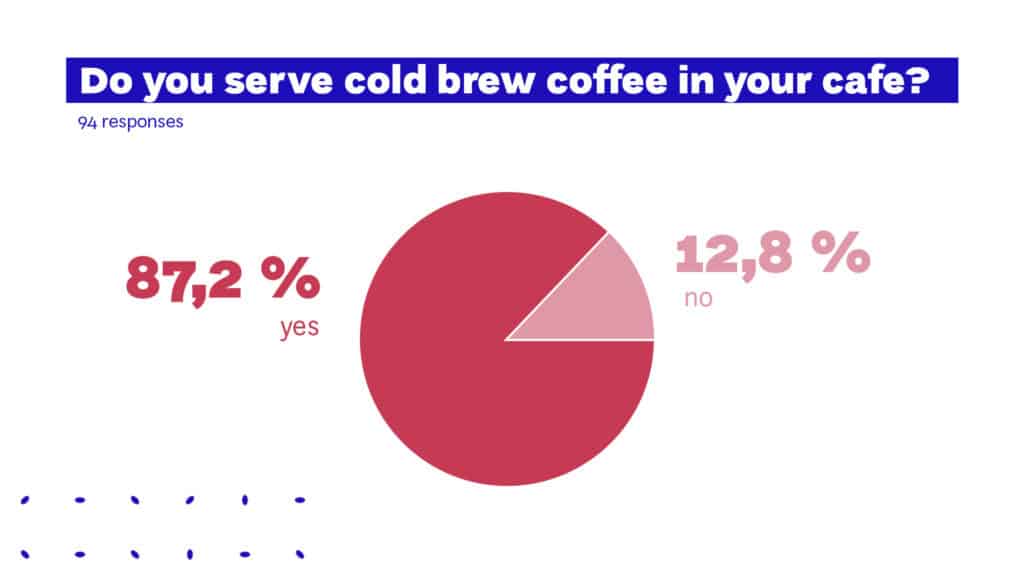

Cold Brew has been a buzzword of the coffee industry for the past couple of years and has become a standard offering on the menu of cafes across the world. In our recent poll among European speciality cafes in our guides, over 87% of respondents confirmed serving Cold Brew Coffee in their shop.

Apparently, guests love it; it’s good for the business, yet some baristas & cafe owners have mixed feelings. Often they worry about the challenges like long extraction time, hygiene or labour cost. Still, it’s a trend we should pay attention to since the global cold brew coffee is projected to reach $1.63 billion by 2027, according to Allied Market Research.

Thanks to our partnership with Hard Beans, we had been exposed to this topic for a couple of years. In this article, we are taking a close look at cold brew making methods with their pros and cons. We will also discuss the future approach, technological innovations and opportunities for this growing coffee market sector.

What is Cold Brew Coffee and How To Make It?

The essence of cold brew is expressed in its name. In simple terms, it’s just a cold extraction. In a more detailed way, cold brew is an immersion of a raw material (coffee, tea, cascara, herbs and many more) in cold water (or more complex solvent) for a (long) period of time.

Why would you choose it instead of a regular hot brew over ice? Long extraction in low temperature results in different cup characteristics – sweet, bold, with reduced bitterness and acidity. Usually, cold brew provides more caffeine and antioxidants than hot coffee too.

This is the reason why cold brew became vastly popular in the US market in the last decade and booms in Europe, Middle East & Asia nowadays.

Cafes worldwide serve cold brew over ice, with milk or from the tap infused with nitrogen – the famous Nitro Coffee. However, making cold brew in a cafe environment is not the smoothest process and there are plenty of factors that play a part in creating a delicious cup rather than just a generic, flat one. As a reference, you can see how Happy Baristas in Berlin were producing cold brew coffee for their Nitro Coffee back in 2016.

Challenges of Traditional Cold Brew Coffee Production

What does ‘cold’ mean in this case? Well, here is where it gets tricky. In most cases, it’s just the room-temperature water that is used for extraction. In domestic brewing it is easier to put your brewing vessel in a fridge overnight but doing the same with a 30 litres container in the coffee bar might be impossible. Let’s discuss some typical cold brew coffee making challenges in the cafe environment.

1 – Long extraction time

Traditional cold brew is extracted for 12 to 24 hours. This is the key to its cup profile but also a major challenge for consistency and hygiene, not to mention the food safety of a final product. Long exposure of a coffee bed in a room temperature is the perfect environment for oxidation and microbial growth.

2 – Oxidation & food safety

Oxidation leads to a lack of cleanliness in a cup, dull flavor and spoiled aroma. On top of that, there is no high temperature to sterilize the brew (like with regular hot brewing), so it can be potentially hazardous unless you ensure the most restrictive hygiene standards.

3 – Consistency

Busy cafe environment and uncontrollable variables lead to inconsistent brew profiles. If you run out of cold brew for a day, the next batch will be ready no sooner than tomorrow. One time you will brew it longer; another time a bit shorter as you really need to start serving it to your thirsty guests.

Filtration also plays a part in consistency – single-use paper filters that are standard in the traditional cold brew making need dripping time to obtain full beverage yield. This takes time, and in a rush – you will be forced to either skip that phase or squeeze your filters to reduce the dripping time. That way or another, you end up with inconsistent taste.

4 – Costs

Single-use paper filters generate additional cost of operation. On top of that, we can’t forget about the labor cost of preparing, filtering and manually cleaning the cold brew equipment. All of that disturbs the bar workflow and top up in costs section day by day.

Reading all that out, one can be discouraged to consider cold brew coffee at all. No wonder many baristas who did their research are not big supporters of cold brew coffee production. However, there is chance for improvement with the new cold brew coffee making technologies.

As pointed out by Maciej Duszak, Head of Beverages at Hard Beans: “Through experiments, fast prototyping & partnerships with universities, we learned how to extract cold brew coffee in minutes instead of hours, and thanks to that, we were able to solve all the other problems with cold brew production.”

The Future of Cold Brew Coffee is New Technology

For the last decades, coffee brewing techniques have become advanced, scientifically driven and user-friendly. Automated espresso machines, built-in scales, refractometers and other technologies enabled baristas to control the brewing process better, extract more flavors and reduce operational effort. But for some reason, cold brew coffee has been left out.

Luckily for the industry, things are moving forward with Hardtank technology developed by Hard Beans in Poland and ColdBRU technology from MARCO in Ireland. Let’s look at both cases in detail to better understand their solution to cold brew coffee production.

Hardtank Technology by Hard Beans

Hardtank Cold Brew Technology is one example of a creative and practical approach to this ancient brewing technique. The research & development started back in 2018 and since then, resulted in the series of devices dedicated to cafes, hotels, restaurants, or anyone else serving cold brew.

The key innovation that impacts everything else is speed. Hardtank produces cold brew coffee that is ready to serve and drink in as short as 45 minutes!

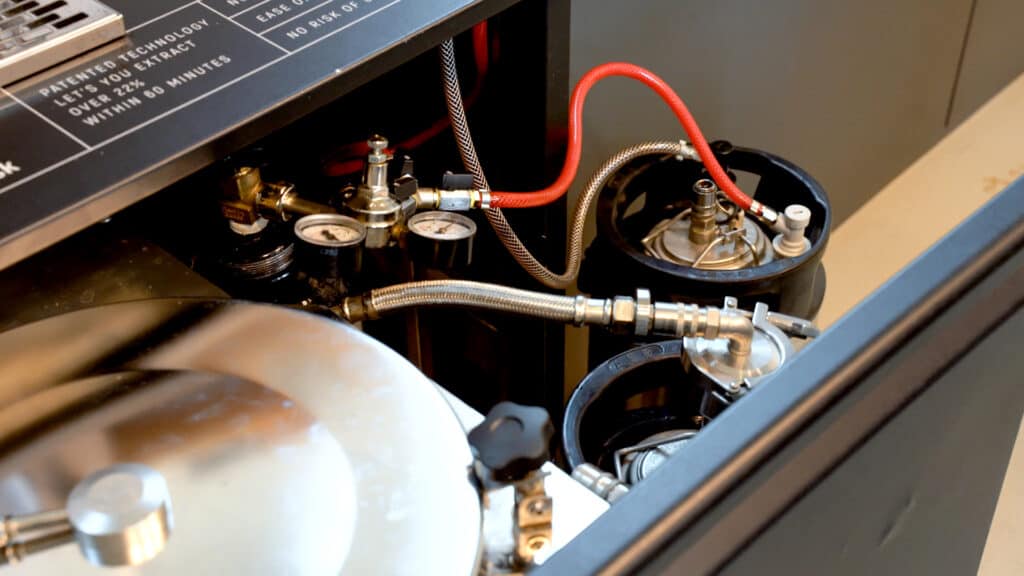

When coffee is extracted in such a short time in a sealed environment, there is hardly any oxidation at all. This leads to solving the next problem, hygiene. Hardtank devices are equipped with automated cleaning and sanitation systems that reduce potential hazards to a minimum without any barista involvement. Everything happens automatically in stainless steel housing.

Consistency is not an issue either, as there are no paper filters in this system, and the extraction process is controlled digitally, from precise water dosing to pumping the beverage into the keg automatically. This further reduces potential points of contamination to a minimum.

Eliminating paper filters and reducing barista engagement, drops down the cost of operation significantly. Preparing a batch of cold brew with Hardtank takes no more than 15 minutes of labor time, including a clean-up time.

There are 2 devices available on the market right now.

- Hardtank, under-counter machine that can produce up to 18 litres of cold brew at once (and 250 litres per day),

- Baby Hardtank, countertop machine that produces up to 6 litres of cold brew at the same time (and 32 litres per day).

Hard Beans started small but recently teamed up with a major coffee machines producer FETCO to manufacture Hardtanks in their US-based factory and to bring it to the global coffee market.

ColdBRU Technology by MARCO

Marco Beverage Systems have bean in the game of designing and manufacturing beverage dispense solutions for over 40 years. Previously, we have seen primarily water dispensing systems and (hot) coffee brewing devices. ColdBRU is product that aims to disrupt the cold brew making market.

ColdBRU is a standalone device that makes up to 7 liters of coffee brew coffee concentrate in under 3 hours. That’s up to 19 liters of ready to drink cold brew when diluted. The specifications for cold brew concentrate that ColdBRU aims to produce is average 19% extraction and 4% TDS.

There is no need to pre-wet or stir the grinds. There is no paper filter involved in the browning neither, just a reusable metal filter. As a preparation for the brewing process, there is tamping protocol that barista should follow in order to maximasie the coffee extraction.

A benefit is a compatibility with Marco’s POUR’D Concentrate Dispense System that allows an easy and streamlined coldbrew operation behind the bar.

Overall, the future of cold brew coffee looks bright, with innovative technologies such as Hardtank and ColdBRU making the process more efficient and consistent. As the popularity of cold brew continues to grow, it is likely that more advances in cold brew-making techniques will emerge, further revolutionising the coffee industry

Disclaimer: Hard Beans and Marco are advertising partners of European Coffee Trip